IEC/BS standard XLPE-insulated low-voltage (LV) power cables are suitable for applications with rated voltages up to 0.6/1kV. Henan Jiapu Cable offers various configurations, including single-core and multi-core options, with optional steel wire armor to enhance strength and resistance to interference.

Application :

IEC/BS standard XLPE-insulated low-voltage (LV) power cables are primarily used for power transmission and distribution. They may be directly buried underground or installed in cable trays and tunnels, and are also suitable for industrial environments such as power stations, factories, and mining operations. XLPE Insulated Cable is laying indoors and outdoors. Able to bear certain traction during installation, but not external mechanical forces. Laying single core cable in magnetic ducts is not allowed. Cross-linked polyethylene cables may be manufactured using three processes (peroxide, silicone, and irradiation cross-linking) to produce various flame-retardant and non-flame-retardant cross-linked polyethylene cables. Flame-retardant cables encompass various types including low-smoke, low-halogen, low-smoke zero-halogen, and zero-smoke zero-halogen, and are categorised into three grades: A, B, and C.

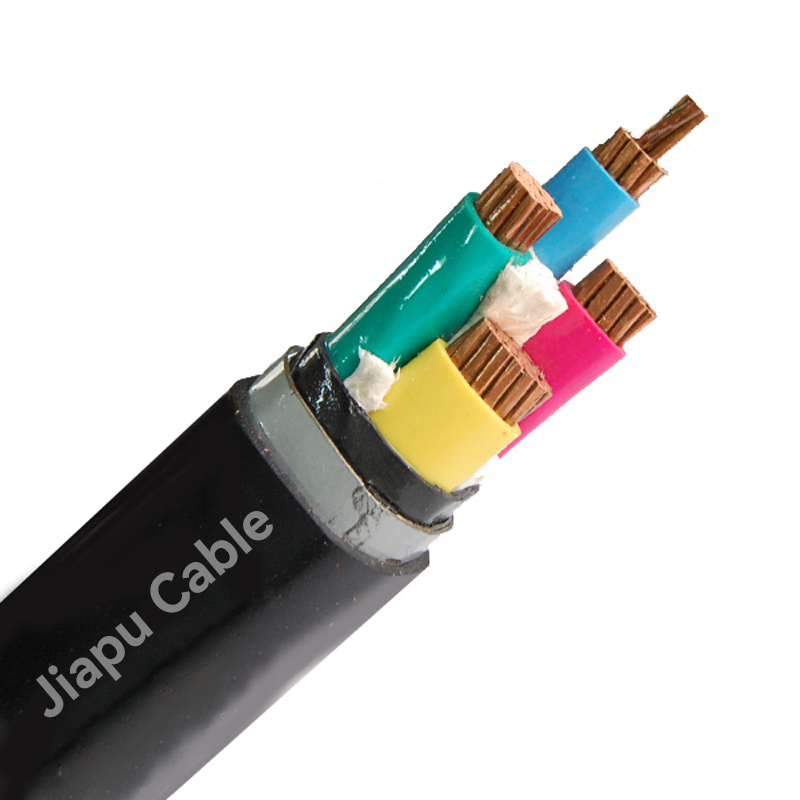

Construction:

Conductor: Class 2 stranded copper conductor or aluminium conductor

Insulation: XLPE exhibits strong resistance to acids, alkalis, and oils. Its combustion products are primarily water and carbon dioxide, posing minimal environmental hazard.

Armour method: Unarmored or Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA)

Outer sheath: PVC (polyvinyl chloride), or rodent and termite-resistant PVC (optional)

Characteristics :

Rated voltage: 0.6/1 kV

Rated temperature: 0°C to +90°C

Bending radius: 1.5mm² to 16mm²: 6 x outer diameter

25mm² and above: 8 x outer diameter

Fire resistance: IEC 60332 Part 1, BS4066 Part 1

Core color:

1 core: brown

2 cores: brown, blue

3 cores: brown, black and grey

4 cores: brown, black, gray and blue

5 cores: brown, black, gray, blue and green/yellow

600/1000 V-Two core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of extruded bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight |

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km |

| 1.5* | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.2 | 355 |

| 1.5 | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.6 | 370 |

| 2.5* | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15 | 400 |

| 2.5 | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15.4 | 415 |

| 4 | 4.61 | 0.7 | 1 | 0.9 | 1.8 | 16.4 | 480 |

| 6 | 3.08 | 0.7 | 1 | 0.9 | 1.8 | 17.6 | 570 |

| 10 | 1.83 | 0.7 | 1 | 1.25 | 1.8 | 20.3 | 820 |

| 16 | 1.15 | 0.7 | 1 | 1.25 | 1.8 | 22.3 | 1030 |

| 25 | 0.727 | 0.9 | 1 | 1.6 | 1.8 | 26.3 | 1530 |

| 35 | 0.524 | 0.9 | 1 | 1.6 | 1.8 | 28.5 | 1840 |

| 50 | 0.387 | 1 | 1 | 1.6 | 1.8 | 30.9 | 2070 |

| 70 | 0.268 | 1.1 | 1 | 1.6 | 2 | 34.9 | 2670 |

| 95 | 0.193 | 1.1 | 1.2 | 2 | 2.1 | 40.1 | 3660 |

| 120 | 0.153 | 1.2 | 1.2 | 2 | 2.2 | 43.7 | 4350 |

| 150 | 0.124 | 1.4 | 1.2 | 2 | 2.3 | 47.5 | 5160 |

| 185 | 0.0991 | 1.6 | 1.4 | 2.5 | 2.5 | 53.3 | 6600 |

| 240 | 0.0754 | 1.7 | 1.4 | 2.5 | 2.7 | 59.1 | 8100 |

| 300 | 0.0601 | 1.8 | 1.6 | 2.5 | 2.8 | 64.1 | 9660 |

| 400 | 0.047 | 2 | 1.6 | 2.5 | 3.1 | 71.3 | 12000 |

| 500 | 0.0366 | 2.2 | 1.6 | 3.15 | 3.3 | 79.8 | 15500 |

*Circular solid conductors (Class 1).

All other conductors Circular stranded or circular stranded compacted (Class 2).

Cables conform to BS 5467 and generally to IEC 60502 – 1.

600/1000V-Three core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

*Circular solid conductors (Class 1).

Conductors including 16sqmm circular stranded (Class 2).

25sqmm and above shaped stranded conductors(Class 2)

Cables conform to BS 5467 and generally to IEC 60502-1.

600/1000V-Four core copper conductor xlpe insulated pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm² | Ω/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

*All conductors shaped stranded(Class 2)

Cables conform to IEC 60502-1

Drum size given above are for cables with extruded bedding

More Product

Send An Email

Send An Email