Used for control and power applications in chemical plants, , industrial plants, utility substations and generating stations, residential and commercial buildings.

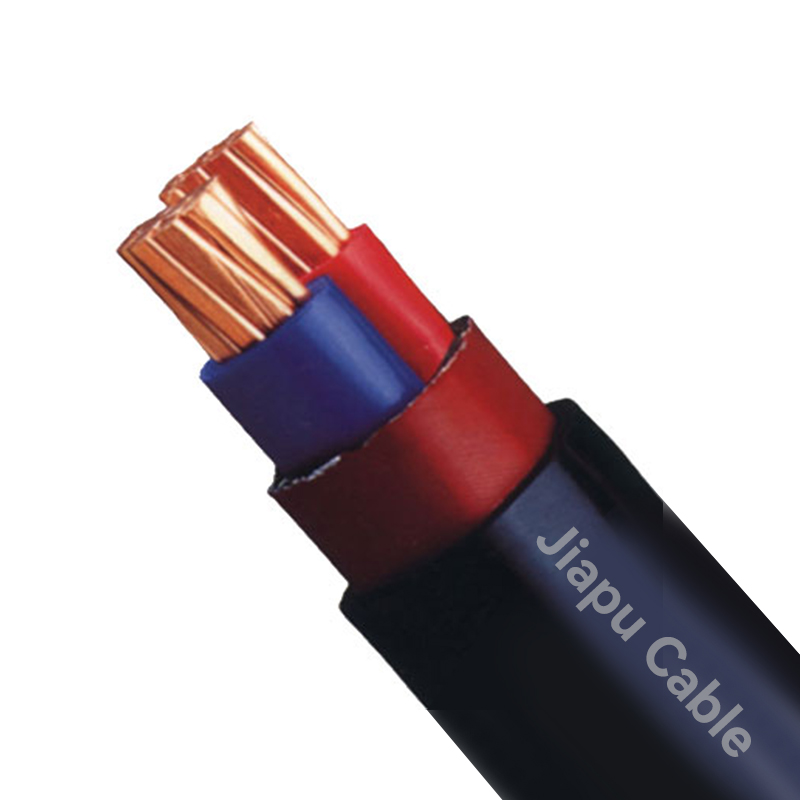

Construction:

1. Conductor: Class B stranded, annealed bare copper per ASTM B-3 and B-8

2. insulation: Polyvinyl Chloride (PVC), nylon covered per UL 83 for Type THHN/THWN

3. Color code: Conductors are color coded per ICEA Method 4 (printed numbers)

4. Assembly: Insulated conductors are cabled together with fillers as necessary to make round

5. Overall jacket: Sunlight-resistant Polyvinyl Chloride (PVC) per UL 1277

Standards:

ASTM B3 Standard Specification for Soft or Annealed Copper Wire

ASTM B8 Concentric-Lay-Stranded Copper Conductors

UL 83 Thermoplastic Insulated Wires and Cables

UL 1277 Electrical Power and Control Tray Cables

UL 1685 Vertical-Tray Fire Propagation and Smoke Release Test

ICEA S-58-679 Control Cable Conductor Identification Method 3 (1-BLACK, 2-RED, 3-BLUE)

ICEA S-95-658 (NEMA WC70) Power Cables Rated 2000 Volts or Less for the Distribution of Electrical Energy

Properties:

Max.rated temperature of conductor: Nominal Operating 90℃.

short circuit:(Max.for 5 secs)250℃.

Temperature of laying, in air 25℃

Underground 15℃

For laying, single core, triangle laying for three cables.

Depth of laying in direct: 100cm

Coefficient of thermal resistivity of soil 100℃.cm/w

The cable can be laid without drop restriction, and the environment temperature shall not be lower than 0℃.

Single core, steel tape armoured cable should be only applied to direct-circuit line.

For nominal insulation thickness, size of armour,over-diameter,weight and current rating of flame-retardant

cable of class A, B,C,which should refer to the value of general cable.

Sheath colours: black with red stripe

Packing: 500m each drum or other length also available on request

Product data sheet

| Nominal Dia. for Copper and Aluminum Conductors | |||||||

| Conductor size | Solid (mm) | Stranded | |||||

| AWG or KCMIL | mm² | Compact (mm) | Class B Compressed | Class B | Class C | Class D | |

| 18 | 0.823 | 1.02 | 1.17 | ||||

| 16 | 1.31 | 1.29 | 1.47 | ||||

| 15 | 1.65 | 1.45 | 1.65 | ||||

| 14 | 2.08 | 1.63 | 1.79 | 1.84 | 1.87 | 1.87 | |

| 13 | 2.63 | 1.83 | 2.02 | 2.07 | 2.10 | 2.10 | |

| 12 | 3.31 | 2.05 | 2.26 | 2.32 | 2.35 | 2.36 | |

| 11 | 4.17 | 2.30 | 2.53 | 2.62 | 2.64 | 2.64 | |

| 10 | 5.26 | 2.59 | 2.87 | 2.95 | 2.97 | 2.97 | |

| 9 | 6.63 | 2.91 | 3.20 | 3.30 | 3.33 | 3.35 | |

| 8 | 8.37 | 3.26 | 3.40 | 3.58 | 3.71 | 3.76 | 3.76 |

| 7 | 10.60 | 3.67 | 4.01 | 4.17 | 4.22 | 4.22 | |

| 6 | 13.30 | 4.11 | 4.29 | 4.52 | 4.67 | 4.72 | 4.72 |

| 5 | 16.80 | 4.62 | 5.08 | 5.23 | 5.28 | 5.31 | |

| 4 | 21.10 | 5.19 | 5.41 | 5.72 | 5.89 | 5.94 | 5.97 |

| 3 | 26.7 | 5.83 | 6.05 | 6.40 | 6.60 | 6.68 | 6.71 |

| 2 | 33.6 | 6.54 | 6.81 | 7.19 | 7.42 | 7.52 | 7.54 |

| 1 | 42.4 | 7.35 | 7.59 | 8.18 | 8.43 | 8.46 | 8.46 |

| 1/0 | 53.5 | 8.25 | 8.53 | 9.17 | 9.45 | 9.50 | 9.50 |

| 2/0 | 37.4 | 9.27 | 9.55 | 10.30 | 10.60 | 10.70 | 10.70 |

| 3/0 | 85 | 10.40 | 10.70 | 11.6 | 11.9 | 12.0 | 12.00 |

| 4/0 | 107 | 11.70 | 12.10 | 13.0 | 13.4 | 13.4 | 13.45 |

| 250 | 127 | 12.70 | 13.20 | 14.2 | 14.6 | 14.6 | 14.60 |

| 300 | 152 | 13.90 | 14.50 | 15.5 | 16.0 | 16.0 | 16.00 |

| 350 | 177 | 15.00 | 15.60 | 16.8 | 17.3 | 17.3 | 17.30 |

| 400 | 203 | 16.10 | 16.70 | 17.9 | 18.5 | 18.5 | 18.5 |

| 450 | 228 | 17.00 | 17.80 | 19.0 | 19.6 | 19.6 | 19.6 |

| 500 | 253 | 18.00 | 18.70 | 20.0 | 20.7 | 20.7 | 20.7 |

| 550 | 279 | 19.70 | 21.1 | 21.7 | 21.7 | 21.7 | |

| 600 | 304 | 20.70 | 22.0 | 22.7 | 22.7 | 22.7 | |

| 650 | 329 | 21.50 | 22.9 | 23.6 | 23.6 | 23.60 | |

| 700 | 355 | 22.30 | 23.7 | 24.5 | 24.5 | 24.50 | |

| 750 | 380 | 23.10 | 24.6 | 25.3 | 25.4 | 25.43 | |

| 800 | 405 | 23.80 | 25.4 | 26.2 | 26.2 | 26.20 | |

| 900 | 456 | 25.40 | 26.9 | 27.8 | 27.8 | 27.80 | |

| 1000 | 507 | 26.90 | 28.4 | 29.3 | 29.3 | 29.30 | |

| 1100 | 557 | 29.8 | 30.7 | 30.7 | 30.78 | ||

| 1200 | 608 | 31.1 | 32.1 | 32.1 | 32.10 | ||

| 1250 | 633 | 31.8 | 32.7 | 32.8 | 32.80 | ||

| 1300 | 659 | 32.4 | 33.4 | 33.4 | 33.40 | ||

| 1400 | 709 | 33.6 | 34.7 | 34.7 | 34.7 | ||

| 1500 | 760 | 34.8 | 35.9 | 35.9 | 35.9 | ||

| 1600 | 811 | 35.9 | 37.1 | 37.1 | 37.1 | ||

| 1700 | 861 | 37.1 | 38.2 | 38.2 | 38.2 | ||

| 1750 | 887 | 37.60 | 38.8 | 38.8 | 38.8 | ||

| 1800 | 912 | 38.2 | 39.3 | 39.3 | 39.3 | ||

| 1900 | 963 | 39.2 | 40.4 | 40.4 | 40.4 | ||

| 2000 | 1013 | 40.2 | 41.5 | 41.5 | 41.5 | ||

| 2500 | 1267 | 44.9 | 46.3 | 46.3 | 46.3 | ||

| 3000 | 1520 | 49.2 | 50.7 | 50.7 | 50.7 | ||

| Conductor Sizes, Insulation Thickness and Test Voltages | |||||

| Rated Circuit Voltage (Phase to Phase) | Conductor size | Nominal Insulation Thickness | AC Test voltage | DC Test Voltage | |

| A | B | ||||

| V | AWG/ KCMIL | mm | KV | KV | |

| 0-600 | 43357.00 | 1.016 | 0.762 | 3.5 | 10.5 |

| 43314.00 | 1.397 | 1.143 | 5.5 | 16.5 | |

| 1-4/0 | 2.032 | 1.397 | 7 | 21 | |

| 225-500 | 2.413 | 1.651 | 8 | 24 | |

| 525-1000 | 2.64 | 2.032 | 10 | 30 | |

| 1025-2000 | 3.175 | 2.54 | 11.5 | 34 | |

| 601-2000 | 43357.00 | 1.397 | 1.016 | 5.5 | 16.5 |

| 43314.00 | 1.778 | 1.397 | 7 | 21 | |

| 1-4/0 | 2.159 | 1.651 | 8 | 24 | |

| 225-500 | 2.667 | 1.778 | 9.5 | 28.5 | |

| 525-1000 | 3.048 | 2.159 | 11.5 | 34.5 | |

| 1025-2000 | 3.556 | 2.921 | 13.5 | 40 | |

| Jacket Thickness | |||||

| Jacket thickness for Single-conductor cables | Thickness of common overall jacket of multiple-conductor cable | ||||

| Calculated dia. of cable under jacket | Jacket Thickness | Calculated dia. of cable under jacket | Jacket Thickness | ||

| Min. | Nominal | Min. | Nominal | ||

| mm | mm | mm | mm | mm | mm |

| 6.35 or less | 0.33 | 0.38 | 10.8 or less | 1.02 | 1.14 |

| 6.38-10.8 | 0.635 | 0.76 | 10.82-17.78 | 1.27 | 1.52 |

| 10.82-17.78 | 1.02 | 1.14 | 17.81-38.10 | 1.78 | 2.03 |

| 17.81-38.1 | 1.4 | 1.65 | 38.13-63.50 | 2.41 | 2.79 |

| 38.13-63.5 | 2.03 | 2.41 | 63.53 and larger | 3.05 | 3.56 |

| 63.53 & later | 2.67 | 3.18 | |||

More Product

Send An Email

Send An Email