Is aluminum cable the best alternative to copper cable? Want to understand this problem, from aluminum alloy cables and copper cable performance differences in all aspects of understanding, and now JiaPu cable with you to explore the aluminum alloy cable is not the best alternative to copper wire cable.

What is aluminum alloy cable?

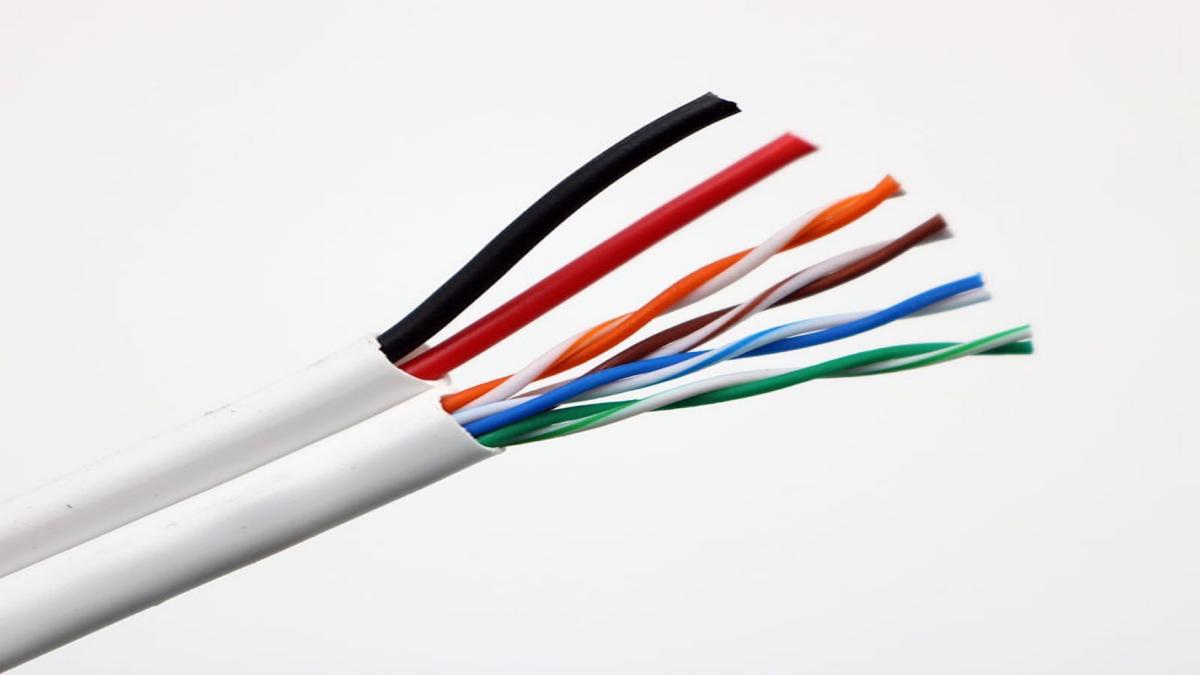

Aluminum alloy power cable is aluminum as the main conductor material, adding copper, iron, magnesium, silicon, zinc, boron and other alloying elements, produced by a special process of aluminum alloy as the conductor of the power cable.

What are the advantages of aluminum alloy power cables over copper core cables?

Improved conductor performance: aluminum alloy power cables due to the addition of alloying elements in pure aluminum, so that the mechanical properties of aluminum alloy conductor has been greatly improved, enhanced bending, creep resistance and corrosion resistance.

Light weight: the conductivity of aluminum alloy is 61.5% of copper, copper is 79% of the flow-carrying capacity, the following table can be seen, almost equal to the flow-carrying capacity of aluminum alloy cable weight is only 65% of the weight of the copper-core cables, transportation and engineering laying of the comprehensive labor costs have also been significantly reduced.

Low price: aluminum alloy cable capacity of about 79% of the copper, aluminum alloy cable to replace the same capacity copper core cable, generally in the copper core cable cross-sectional area increased by 1.5 times the choice of aluminum alloy cable.

Compared with copper cables, aluminum cables have unparalleled advantages over copper cables in terms of weight, price and installation. In other words, in the same electrical properties and better mechanical properties of the premise, aluminum alloy cable economic effect is significant, and a wide range of applications.

Disadvantages of aluminum cables

Aluminum alloy cable has many advantages, but there are some problems should not be ignored, aluminum alloy cable terminals may not be able to keep up with the demand for cables, because of the special nature of the material of aluminum alloy cables, resulting in the choice of material for the terminal port, size, and the degree of matching of the interface at the other end of the cable, in the process of laying and construction there may be a certain amount of trouble. Appearance of fire resistance is low, the fire resistance of the cable mainly depends on the conductor material, cable conductor copper, aluminum and aluminum alloy three, copper melting point of 1083 ℃, aluminum melting point of 660 ℃, the general situation of alloy material than the melting point of the pure metal to be lower, that is to say, aluminum alloy melting point than the pure aluminum, in the fire-resistant this point of view, compared with pure copper or pure aluminum material, aluminum alloy fire-resistant the lowest.

After the above introduction, JiaPu Cable believes that aluminum alloy cable is the best choice to replace the copper conductor cable, although there are still some problems that can not be ignored.

Post time: Nov-08-2023