Do you know the difference between type testing and product certification? This guide should clarify the differences, as confusion in the market may lead to poor choices.

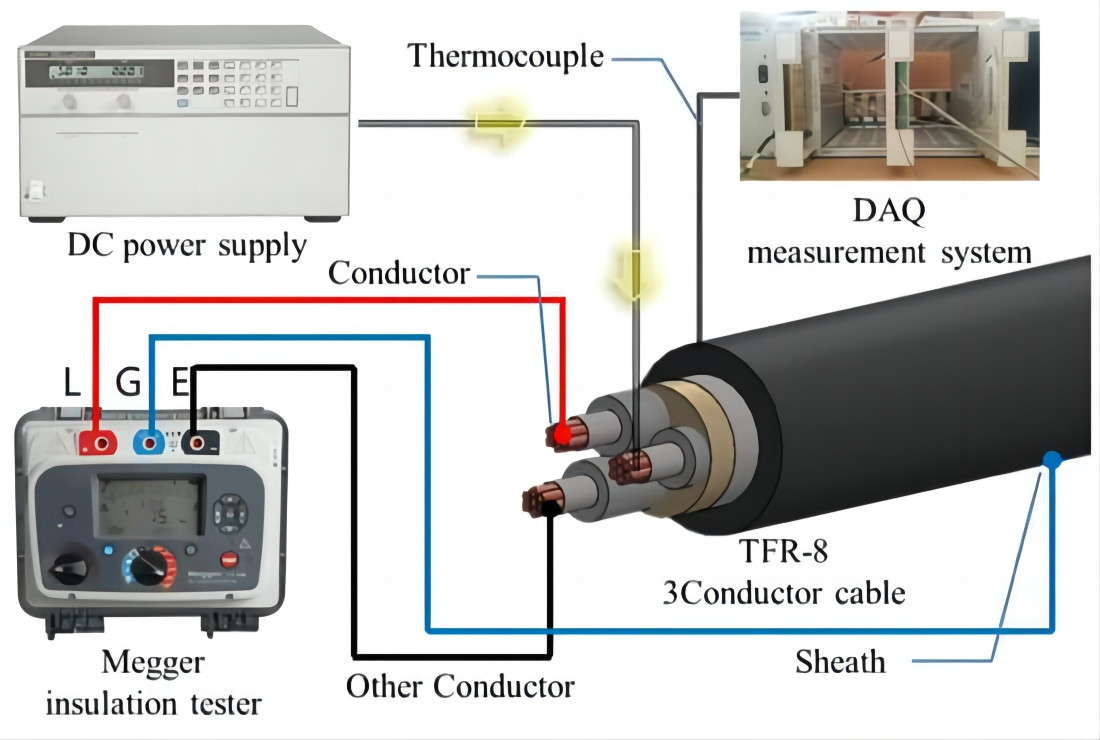

Cables can be complex in construction, with multiple layers of metallic and non-metallic materials, with a range of thicknesses and manufacturing processes that vary depending on the cable functions and application requirements.

The materials used in cable layers, i.e., insulation, bedding, sheath, fillers, tapes, screens, coatings, etc., have unique properties, and these must be consistently achieved through well-controlled manufacturing processes.

Confirmation of the cable’s suitability for its required application and performance is done routinely by the manufacturer and end-user but can also be undertaken by independent organisations via testing and certification.

Third party type testing or one-off testing

It should be remembered that when “cable testing” is referenced, it could be full type testing as per a particular design standard of cable type (e.g., BS 5467, BS 6724, etc.), or it could be just one of the specific tests on a particular cable type (e.g., Halogen content test such as IEC 60754-1 or Smoke emission test as per IEC 61034-2, etc. On LSZH cables). Important points to note with One off-testing by a third party are:

· Type testing on cable is undertaken only on one cable size/sample in a particular cable type/construction or voltage grade

· The cable manufacturer prepares the sample at the factory, tests it internally and then sends it to a third-party laboratory for testing

· There is no third-party involvement in the selection of the samples leading to suspicions that only good or “Golden Samples” are tested

· Once tests are passed, third-party type test reports are issued

· The type test report only covers the samples tested. It cannot be used to claim that non-tested samples conform to the standard or meet the specification requirements

· These kinds of tests are not generally repeated within a 5–10-year timeline unless requested by customers or authorities/utilities

· Therefore, type testing is a snapshot in time, without continuous assessment of cable quality or changes in the manufacturing process or raw materials through routine testing and/or production surveillance

Third party certification for cables

Certification is one step ahead of type testing and involves audits of cable manufacturing factories and, in some cases, annual cable sample testing.

Important points to note with certification by a third party are:

· Certification is always for a cable product range (covers all cable sizes/cores)

· It involves factory audits and, in some cases, annual cable testing

· Certificate validity is usually valid for 3 years but reissued providing routine auditing, and testing confirms ongoing conformity

· The advantage over type testing is the ongoing surveillance of production through audits and testing in some cases

Post time: Jul-20-2023