In the fields of construction, mechanical equipment, etc., cables are an indispensable electrical component. As an essential part of the power transmission and control field, cables are widely used in various industrial manufacturing, railway, petrochemical, shipbuilding and urban construction and other fields. Cables can be divided into single-core cables and multi-core cables according to the number of conductors. This article will introduce the differences between single-core cables and multi-core cables in detail.

Basic concepts of cables

A cable is a device consisting of two or more wires, usually consisting of a metallic conductor, insulating material, and cable sheath. Cables can be divided into two types: single-core cables and multi-core cables. Single core cables have only one metal conductor and are often used for high voltage power transmission. Multicore cables have at least two (or more) conductors and are usually used in low voltage control or communication systems.

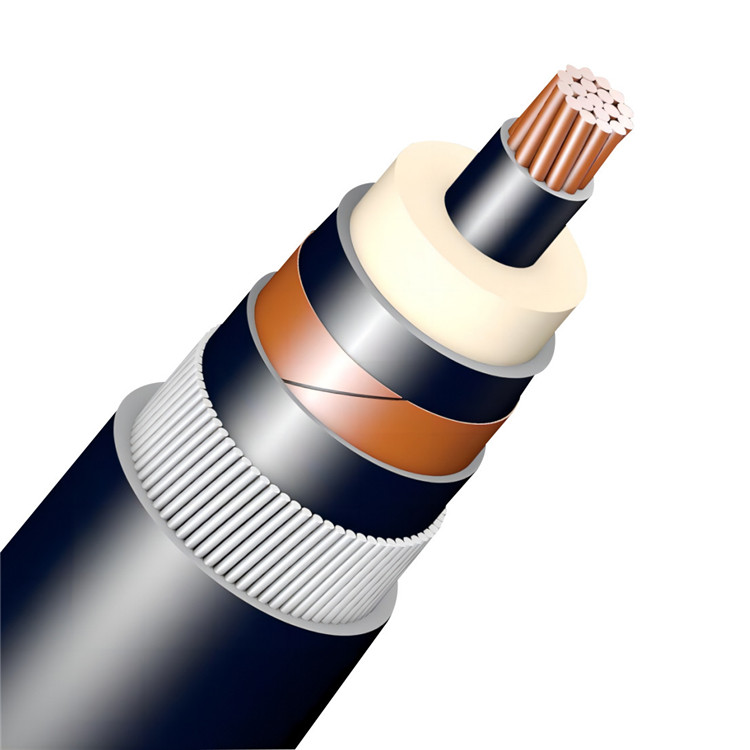

What is a single core cable

A single core cable is a cable with only one conductor. Its main feature is that it has high insulation performance and good withstand voltage capability, and is suitable for transmission of high voltage and large current. Since single-core cables have only one conductor, they produce much less electromagnetic interference than multi-core cables, which is important for applications that require a high degree of precision. The single-core cable also has a small outer diameter and good anti-corrosion performance, which is suitable for installation in narrow spaces.

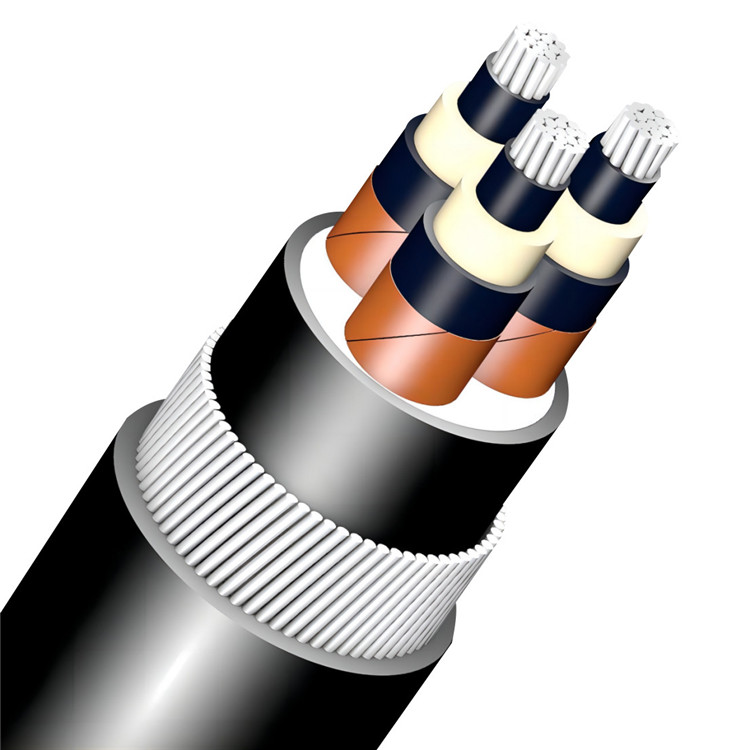

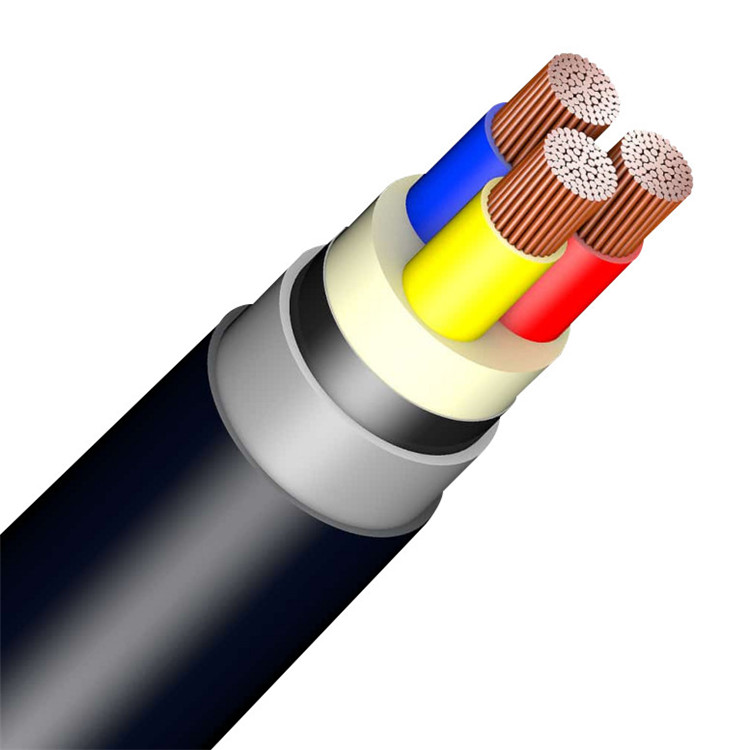

What is a multi-core cable

A multi-conductor cable is a cable consisting of multiple conductors. Its main feature is that it can transmit multiple electrical signals or power signals at the same time, so it is suitable for low-voltage control and communication systems, such as data transmission, telephone lines, etc. Multi-core cables can be further divided into different types such as twisted pair, coaxial cable and shielded cable for different application scenarios. The number of conductors in multi-core cables is large, resulting in increased mutual electromagnetic interference, but the use of appropriate shielding materials can effectively reduce the impact of electromagnetic interference.

Single-core cable VS. Multi-core cable

Number of conductors: Single-core cables have only one conductor, while multi-core cables have multiple conductors.

Scope of application: Single-core cables are suitable for scenarios where high voltage and high current need to be transmitted, such as oil refining, chemical industry, metallurgy and other industries. Multi-core cables are suitable for communication, data transmission, control systems, railway signal transmission and other fields, and can also be used for power supply of electrical equipment inside buildings and signal transmission on robots and mechanical equipment.

Anti-interference ability: single-core cable has high insulation performance and withstand voltage ability, and the electromagnetic interference is relatively small. The multi-core cable can not only transmit multiple signals at the same time, but also resist external electromagnetic interference to a certain extent.

Application scenarios of single-core cables and multi-core cables

Single-core cables are generally used in high-voltage power transmission systems, transformer wiring, and oil refining, chemical, metallurgical and other industries that need to transmit high-voltage and high-current scenarios. In addition, the single-core cable has better anti-corrosion performance and is also suitable for outdoor operation. Multi-core cables are widely used in communication, data transmission, control systems, railway signal transmission and other fields, and can also be used in power supply of electrical equipment inside buildings and signal transmission on robots and mechanical equipment.

Advantages and disadvantages of single-core cables and multi-core cables

Both single-core and multi-core cables have advantages and disadvantages. The advantage of a single-core cable is that it has high insulation performance and voltage resistance, and at the same time, the electromagnetic interference is relatively small, but because it has only one conductor, it cannot transmit multiple signals. The advantage of multi-core cables is that they can transmit multiple signals at the same time, which is suitable for complex control systems and data transmission scenarios, but their resistance to electromagnetic interference is poor.

How to choose single-core cable and multi-core cable

The purpose of the cable: To choose a suitable cable, you first need to consider its specific use. If it is a scene that needs to transmit high voltage and high current, it is recommended to choose a single-core cable; if it is necessary to transmit multiple signals or the cable needs to withstand certain electromagnetic interference, it is recommended to choose a multi-core cable.

Quality of cables: The quality of cables is an important factor affecting their service life and safety. It is recommended to choose a certified brand product, and pay attention to check whether the cable interface, insulation material and ground connection are in good condition.

Cable length: Whether the cable length is appropriate or not has a great influence on the transmission effect and safety of the cable. Cables that are too long increase the resistance of the cable itself, resulting in increased power loss, while cables that are too short may not be able to transmit power to the target device. Therefore, it is recommended to conduct accurate measurements according to actual needs when purchasing cables.

Environmental climate: The environmental climate also has an impact on the service life and safety of the cable. Some special application scenarios, such as humid environment or high temperature environment, need to select the corresponding cable to ensure its safety and stability.

Conclusion

There are certain differences between single-core cables and multi-core cables in terms of the number of conductors, range of applications, and anti-interference capabilities. When selecting cable materials, it is necessary to select appropriate cable materials according to specific application requirements to ensure that the selected cable materials have better performance and durability. In addition, we also need to pay attention to the installation and use conditions of the cable to prolong the service life of the cable.

Post time: Jul-18-2023