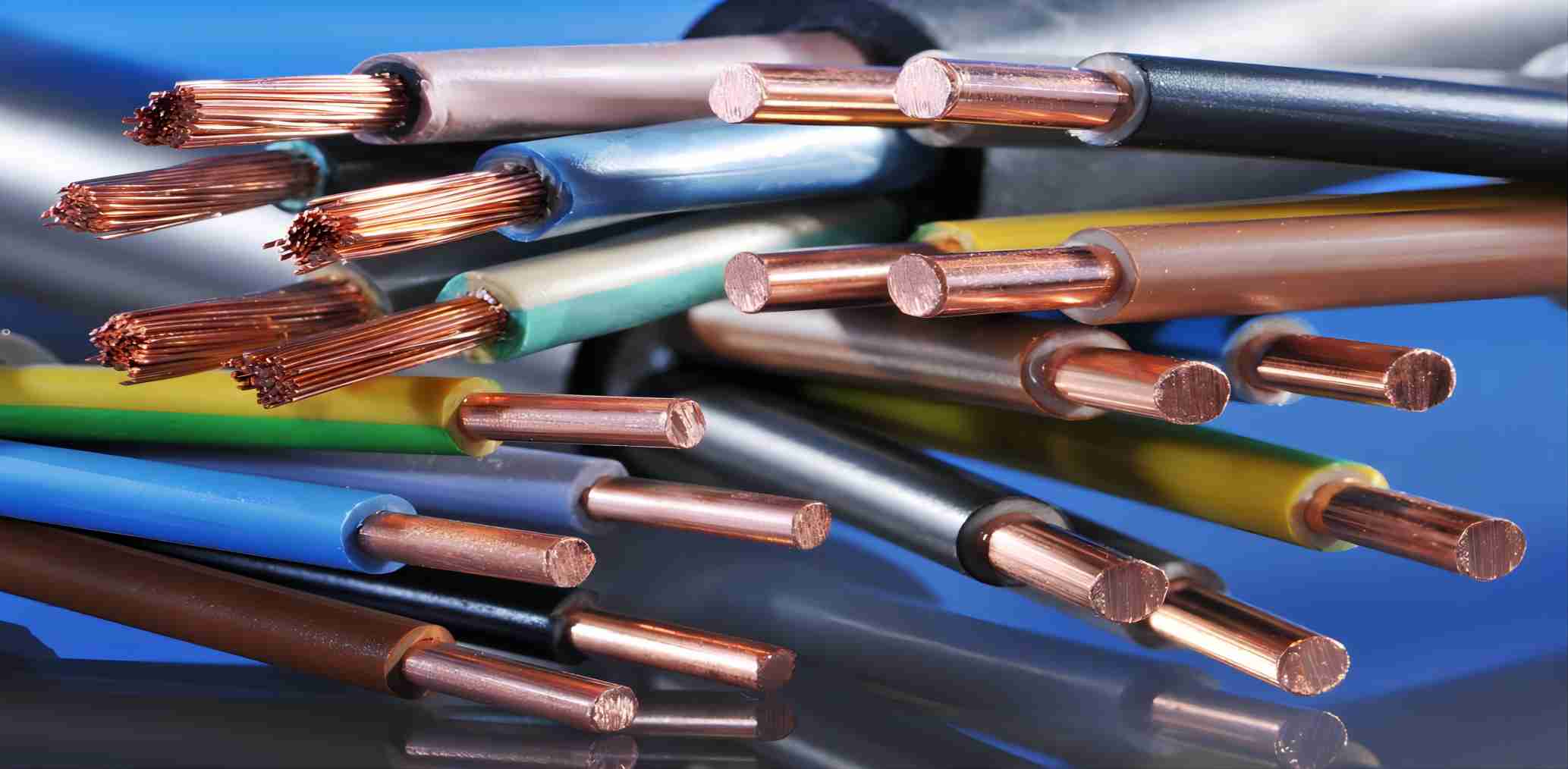

Wires and cables run through our daily lives and we use them to connect appliances, home circuits, and buildings, among other things. Although some people don’t care about the quality of wire and cable, the only way to ensure our safety and productivity is to correctly identify the quality of wire and cable.

Firstly, let’s understand the internal structure of wire and cable. The internal structure of wire and cable consists of several parts: conductor, insulator, insulation material, filler, sheath, etc. The conductor is the part of the cable that transmits electrical energy, representing the transmission capacity of the wire and cable; while the insulator is to keep the insulation between the conductors to avoid electrical energy leakage. Insulation material is different from insulator, it mainly plays an important role as material isolation, fixing conductor, adjusting insulation and appearance decoration. Fillers are internal gap fillers for wire and cable that allow the wire and cable to maintain its external shape and keep moisture out. Sheathing protects the wire and cable from external pressure or corrosion that can damage the internal components.

Secondly, we will discuss how to recognize the quality of wire and cable. First of all, we should pay attention to the electrified safety of wire and cable. For high-quality wire and cable, its interior is made of high-quality materials and technology, and the conductor is equipped with high-quality insulating materials, which have high resistance to high voltage and electric shock. Unlike low-quality wire and cable with incomplete internal structure, insufficient uniformity of insulation material and short service life. We can judge whether the product meets the relevant safety standards by checking the signs and certificates of the wire and cable.

Thirdly, wire and cable quality also depends on its long-term service life. High-quality wire and cable has a longer service life because of the quality of the filler that prevents moisture from entering the interior and the higher quality of the conductors and insulators inside the wire and cable. By looking at the physical characteristics of the materials inside the wire and cable, such as texture and softness, we can make a preliminary judgment of the internal quality of the wire and cable.

Fourth, you also need to consider the abrasion resistance of the wire and cable. High-quality wire and cable in the sheath is usually used in polyvinyl chloride (PVC) and other wear-resistant materials, these wear-resistant materials are of excellent quality, not easy to be damaged by the physical friction or pulling of the external environment. You can also distinguish quality from the feel and texture of the sheath.

Fifth, we can also distinguish between good and bad quality wire and cable from the price. High-quality wire and cable usually has a relatively high price, while the quality of low-priced wire and cable is usually not as good as high-end products. So when buying wire and cable, we should weigh the quality and price of wire and cable and make a wise choice.

In general, it is very important to correctly identify the quality of wire and cable. Pearl River Cable reminds us that we can judge the quality of wire and cable from the aspects of electrified safety, service life, abrasion resistance, price and so on. Only by choosing high-quality wire and cable can we guarantee the safety of our life and work, and at the same time, it can also bring us a more stable and long-lasting experience.

Post time: Sep-14-2023